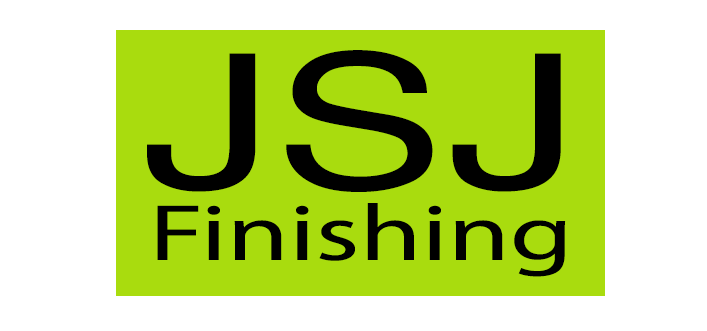

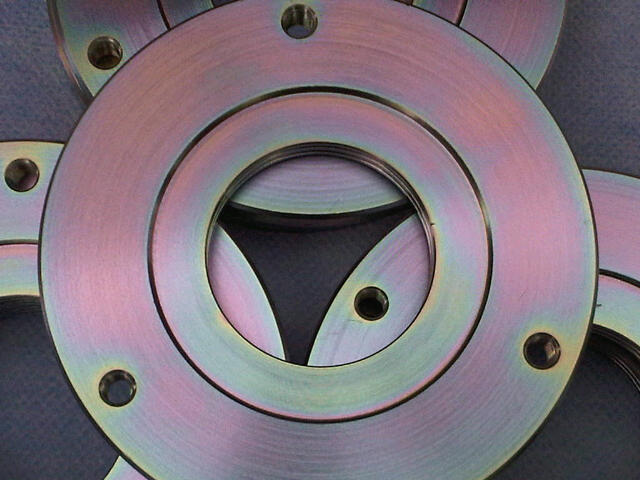

Our Zinc Plating Service is performed to the highest standard on our fully automatic Vat and barrel lines and is processed to customers specifications, Quality is paramount this is why we fully inspect ever part and is checked with our in house XRF (X-Ray Fluorescence test equipment) checking for deposit thickness. We also run to ISO 9001 standards.

Zinc Plating Process

Zinc plating is electrodeposited thin coating of zinc onto the surface of another metal component, known as a substrate. The zinc coating creates a physical sacrificial barrier that prevents rust from reaching the substrate metal. Zinc is chosen because of its ability to prevent corrosion. At JSJ Finishing Ltd we usually deposit between 8-12 µm of zinc in our fully automatic Vat zinc line and Barrel Line; we can of course work with clients if you require more/less deposit.

Our Process Plant

On our 8ft fully automatic Vat Line and Barrel Line we can produce very high volumes of components ranging from very small components to 2m long components at the highest on quality. In our onsite lab we have the facilities to maintain our solutions at their optimum working parameters on a daily basis and let’s not forget the in XRF (X-Ray Fluorescence test equipment) for checking and producing reports on deposit thickness. We also have our own transportation with our 3.5t curtain sided tuck for deliver and collection of customers goods.

We offer a range of post plating treatments:

- Trivalent passivates (yellow and clear) RoHS Compliant

- Hexavalent passivates (yellow)

- Sealants

- Hydrogen De-embrittlement

If you require more information about Zinc plating, please do not hesitate to contact us.