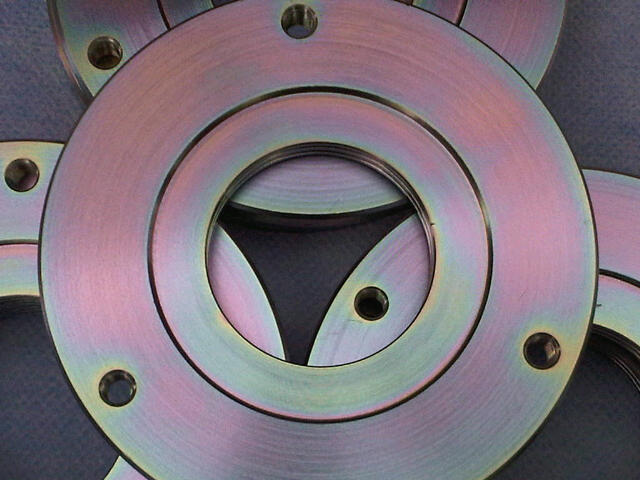

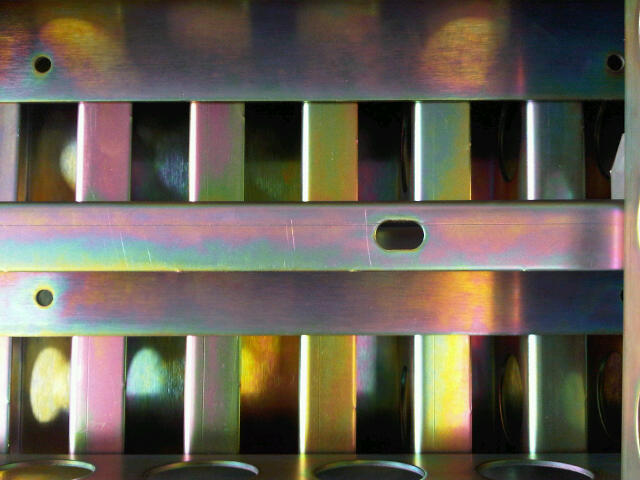

All of our Anodising Service is performed to the highest standard on our 6Ft manual lines and is processed to customers specifications, Quality is paramount this is why we fully inspect every part and is checked. We also run to ISO 9001 standards.

Anodising Process

Anodising is a process that is used to form an aluminium oxide layer on a base material. While anodising does work for several other base materials, aluminium responds the most effectively to anodising. Anodising is used not only for corrosion resistance, but also for wear resistance and the dyeing aluminium. This aluminium oxide is not applied to the surface like paint or plating, but is fully integrated with the underlying aluminium substrate this means it cannot chip or peel. It has a porous structure that allows for secondary processes such as colouring and sealing.

Anodizing is accomplished by immersing the aluminium into an acid electrolyte bath and passing an electric current through the part. A cathode is mounted to the inside of the anodizing tank; the aluminium acts as an anode, so that oxygen ions are released from the electrolyte to combine with the aluminium atoms at the surface of the part being anodized. Anodizing is, therefore, a matter of highly controlled oxidation, the enhancement of a naturally occurring phenomenon.

Our Process Plant

On our 6ft Vat Line we can produce high volumes of components ranging from very small to larger components at the highest quality. In our onsite lab we have the facilities to maintain our solutions at their optimum working parameters on a daily basis. We also have our own transportation with our 3.5t curtain sided truck for delivery and collection of customers' goods.

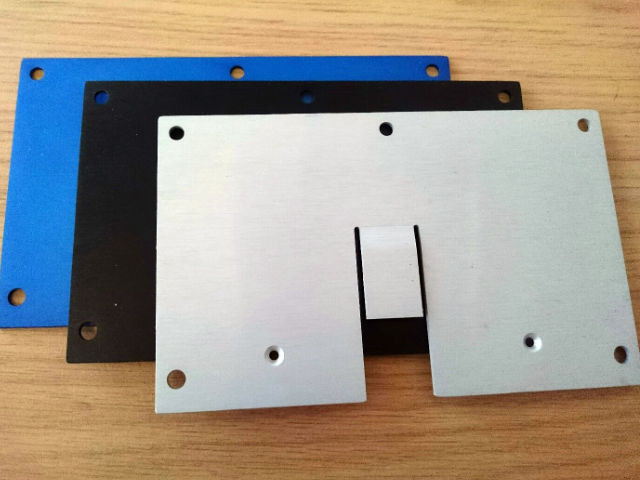

We offer a range of post treatments:

- Black dye

- Red dye

- Cold seals

- Hot seals

If you require more information about Anodising, please do not hesitate to contact us.