We provide electropolishing of Stainless Steel, we mainly work with grades 304 and 316 and also provide pickling and passivating that goes side by side with this finish.

We provide electropolishing of Stainless Steel, we mainly work with grades 304 and 316 and also provide pickling and passivating that goes side by side with this finish.

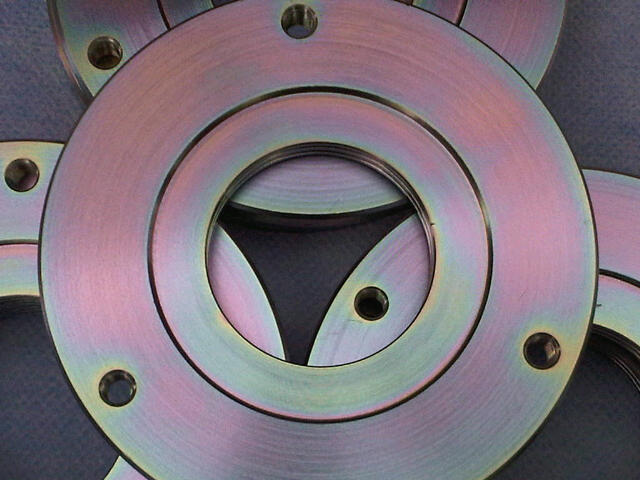

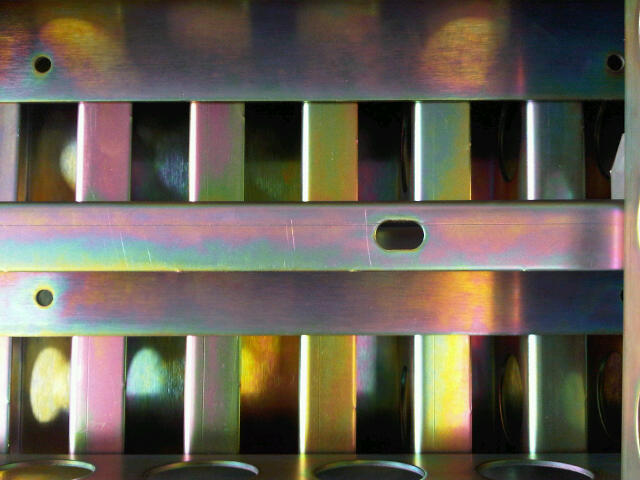

Electropolishing is a reverse current process that removes rather than deposits. It is run at between 8 - 15 volts and works by passing a direct current directly through the anodically connected part jigged in our electropolishing vat. This process removes contamination and debris from machining, welding and mechanical polishing, it smoothes edges and corners and it improves surface reflectivity. Achieving better corrosion resistance; parts are easier to clean, with lower build up and bacterial growth. Pickling and Passivation will remove discolouration from welding, ferrous contamination and clean to extend the life of products