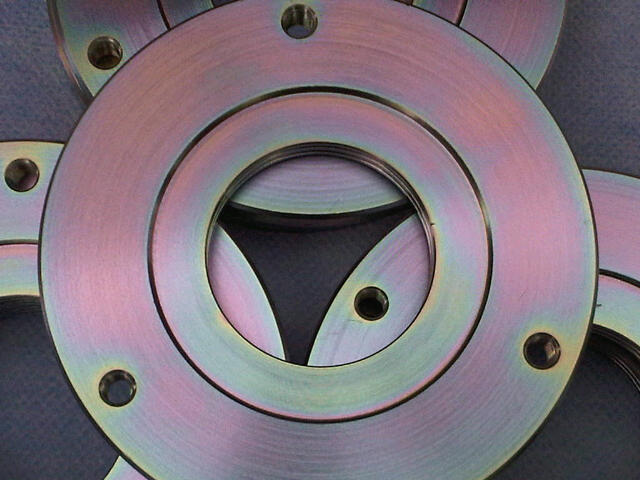

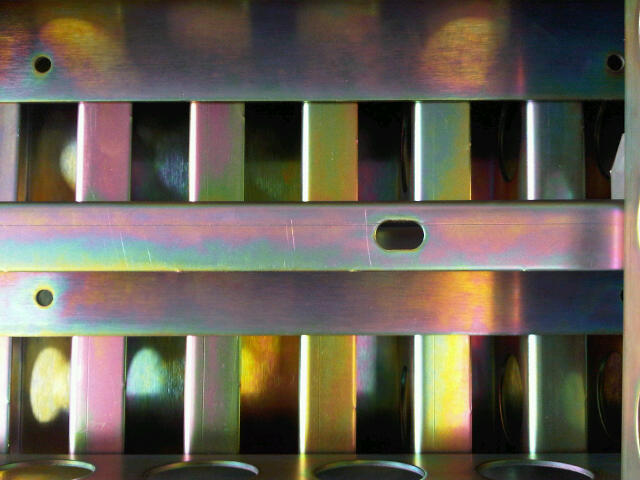

Bright Dipping copper and brass alloys is an acid based chromate conversion coating used to protect and add shelf life to the base material.

The parts are first cleaned to remove the oil and dirt that may be on them from processing and manufacturing. After the parts are cleaned, the parts are then processed with the acid-based chromate conversion coating.

The film that forms adds shelf life and prolongs future tarnish and corrosion to the base material. We can ether rack or barrel plate this deposit in our 3ft vats.

If you require more information about Bright Dip, please do not hesitate to contact us.